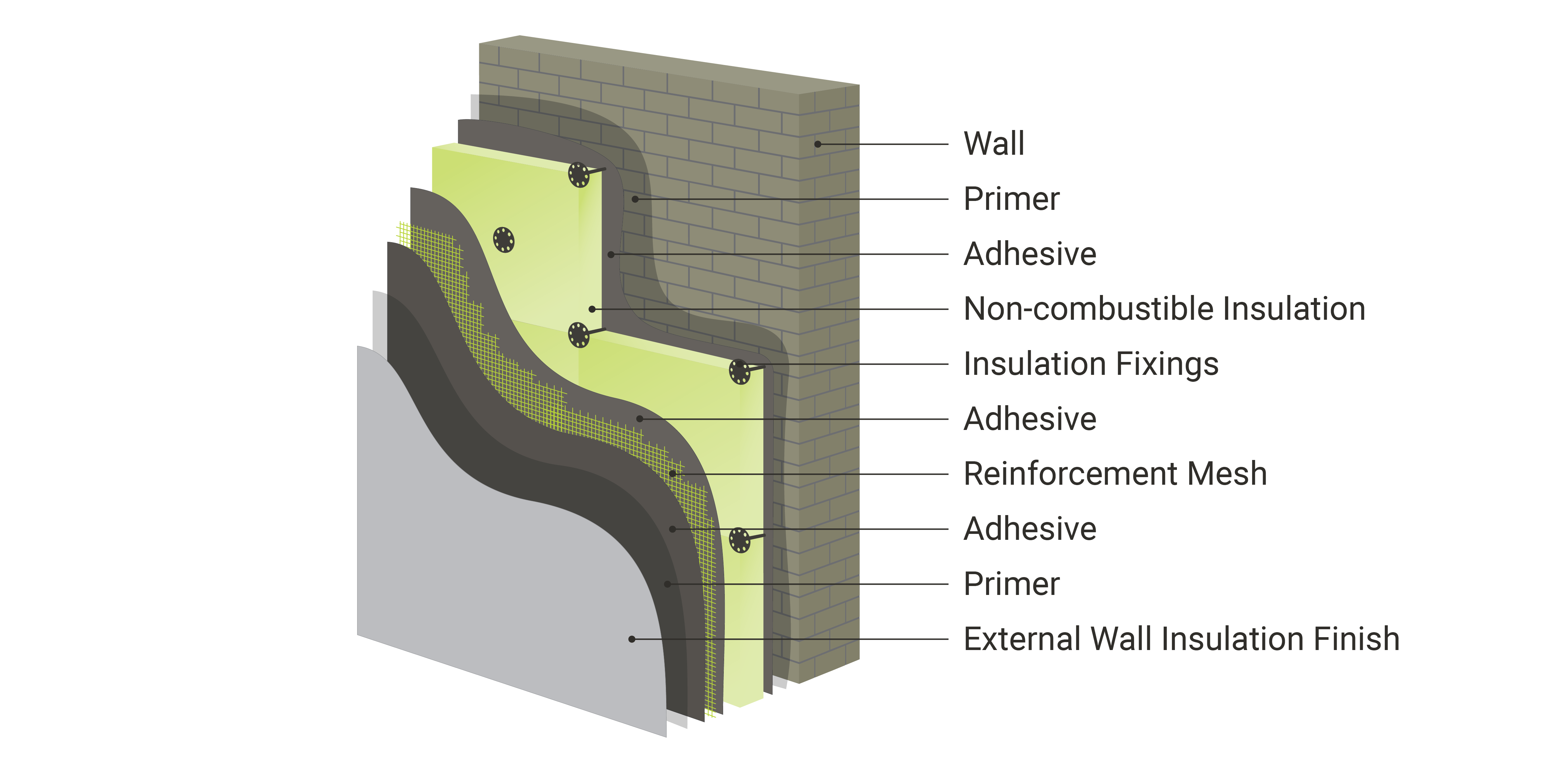

An EWI facade (External Wall Insulation) is a system that involves applying a layer of insulation material to the exterior walls of a building before covering it with a protective and decorative finish, such as render or brick slips.

EWI facades significantly reduce heat loss, making buildings more energy-efficient whilst also improving their appearance. This proven method is widely used for upgrading the thermal performance of existing buildings and is a preferred choice for achieving high energy efficiency standards in new construction.